Centrifuge separators do not have a filter media and hence do not have choking problems or recurring filter media costs. The fully automatic centrifuge separator is of a continuous feed, on-line separator, having very high solid-liquid separation efficiency up to 5 microns particle size.

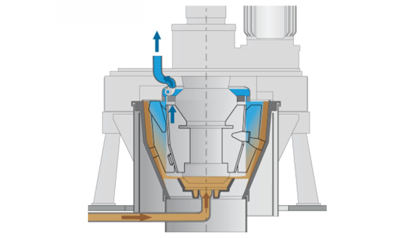

The fully automatic centrifuge separator basically consists of housing with a rotor. The special rotor arrangement spins at a very high speed, thus developing the necessary G-force to separate the most difficult of sludge from the water. During operation, the sludge with water is introduced in the separator from the bottom. The sludge suspension is accelerated on rotor speed and guided towards the outer diameter. The solid particles are pressed against the inner side of the sludge insert. Due to the high rotation speed the separated clean water develops approx. 0.5 bars pressure and is routed back to process.

After the separation cycle is over, the rotor decelerates and the residual water is drained. The separator comes to a halt. At standstill, the scrapping drive is automatically activated and the sludge is automatically cleaned. The sludge falls into a trolley placed below the separator. The separator is automatically flushed with water and the cycle keeps repeating. The advanced PLC control system manages the timing and safety features of the separator.

| Technical Data A-25 | |

|---|---|

| Power | 11 kW |

| Rotor Volume | 40 I |

| Sludge Capacity | 40 kg/h |

| Volume Flow | 150 l/min 9 m3/h |

| Acceleration | 1960 g |