-

GRATING SLUDGE REMOVAL SYSTEMS

Highlights

- Efficient Removal of paint sludge from gratings

- Enables safe operating conditions within the paint booth

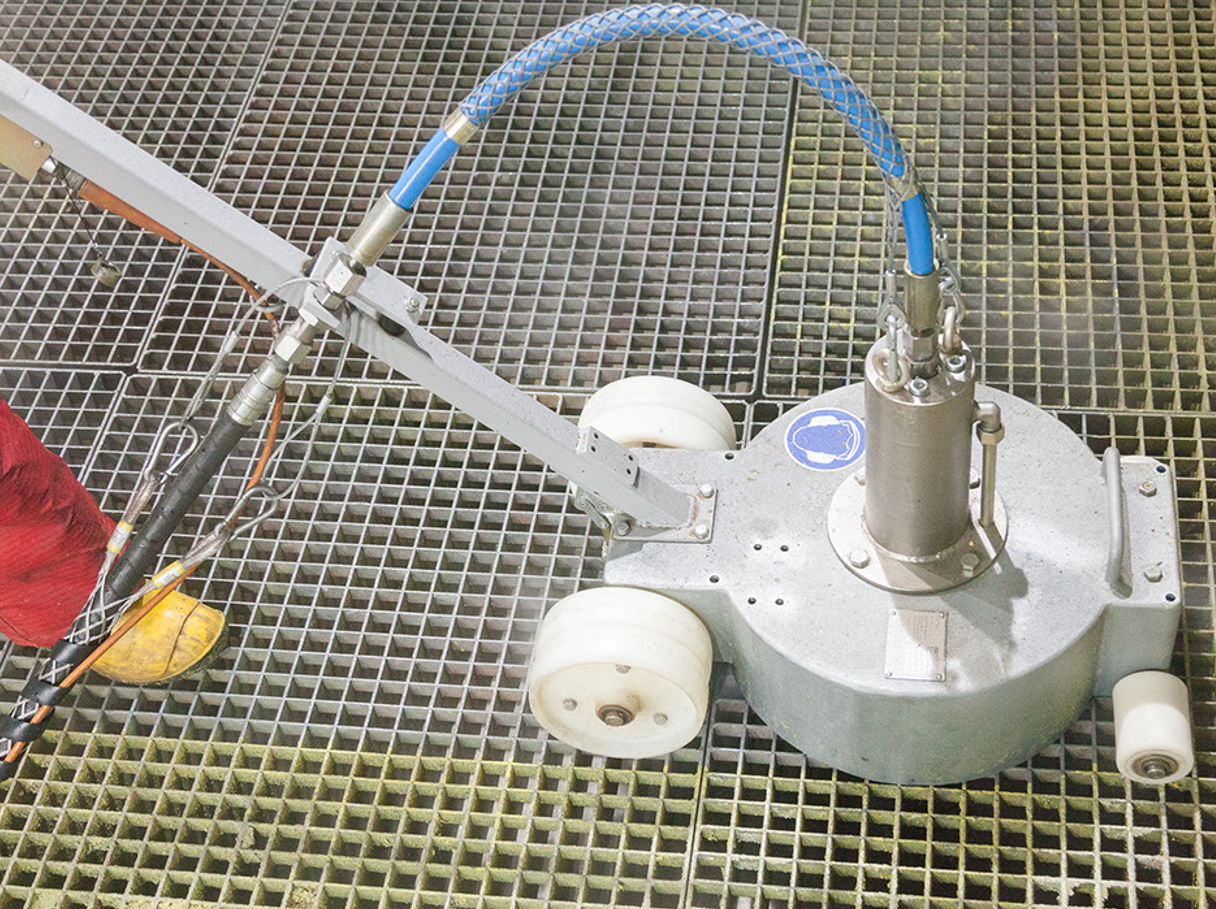

- Manual as well as automatic high-pressure water blasting systems

- Collection and removal system for removed sludge

- Suitable chemical auto-dosing systems for sludge treatment

- Cleaned water reuse

-

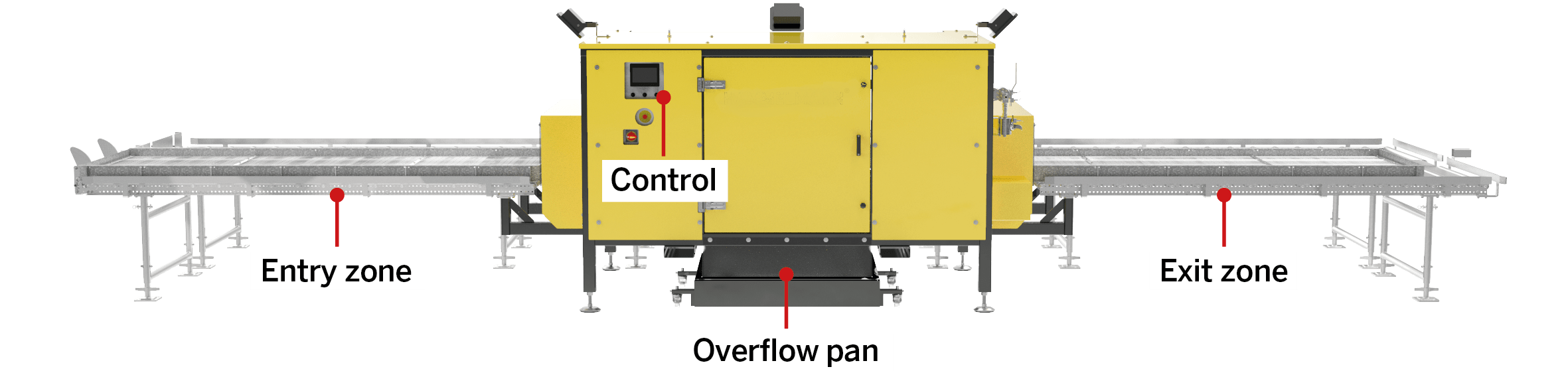

The Grating Sludge Removal System comprises of 2 parts:

- The first section is of the manual or automatic sludge removal system from the gratings.

- If the operation is automated, the first section may also have a conveyorised booth. The gratings are removed from the paint booths and cleaned in this separate line.

- The second section is of the filtration system to collect and remove the sludge from the water.

- The second section may also have chemical dosing systems that may be required based on nature of the removed sludge.

- The cleaned water is usually recycled or a part of it may be sent to ETP.

- The manual version comprises of a hand held high-pressure water blasting gun for removal of grating sludge inside the booth.

- Paint & Phosphate Sludge Dewatering

- Coolant & Oil Cleaning

- Wire Drawing (High Viscosity Lubricant)

- Glass fines removal

- Water & Waste Water Treatment

- Solvent Recovery and bags

- Solid-Liquid Separations

- Phosphate Sludge Removal

- Degrease Sludge Removal

- Sludge Dewatering & Thickening

- Chemicals & Additives

- Solvent Recycler

- Paint Sludge Skimmer

- Food & Beverages

- Acetone Recovery

- Others